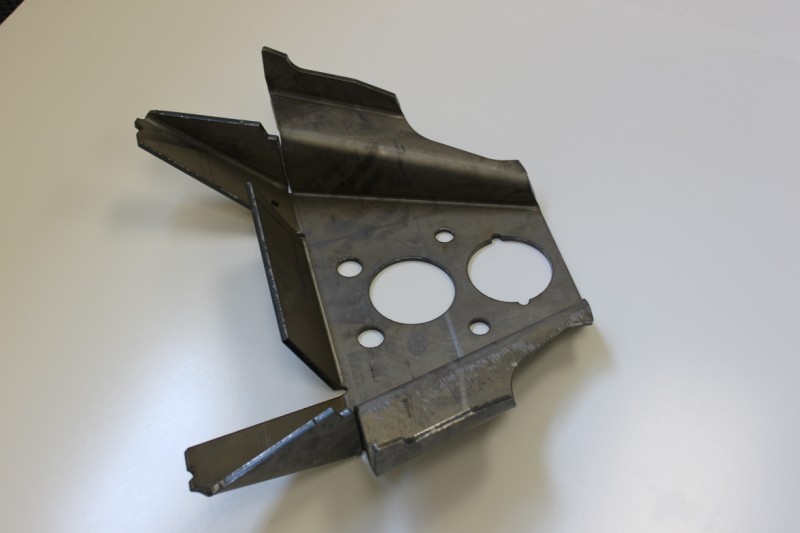

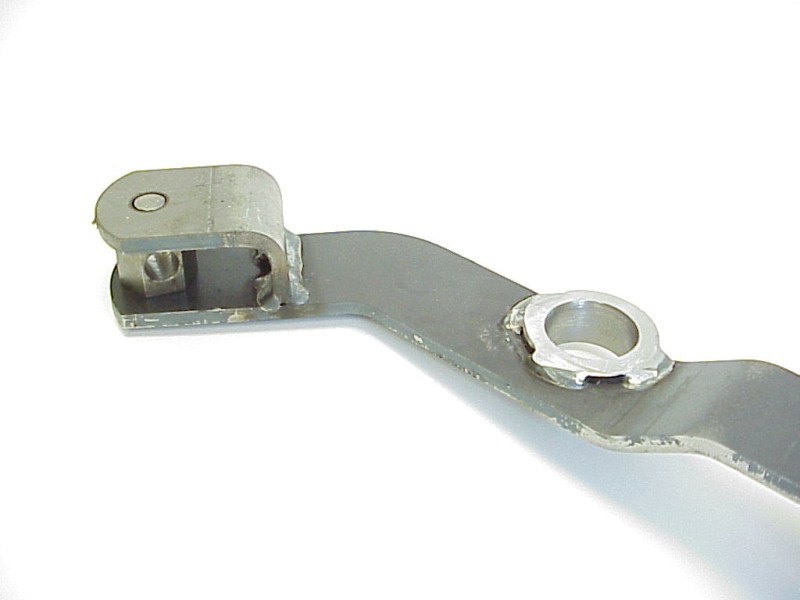

Metal Fabricating and Assemblies

At Bassett Industries, we pride ourselves in helping our customer optimize their metal fabrications, weldments, and assemblies for the unique Bassett processes such as Laser Tube Cutting.

Bassett is a true turnkey supplier that can take your project from raw materials to finished assemblies that are plated and ready for assembly.

Bassett will help you design and tweak your component designs, material selections and assemblies to employ unique and precision Bassett processes such as laser tube cutting, roll bending, CNC machining, precision welding, end forming and sheet metal fabrication to optimize the fabrication and assembly process.

The result is lower-cost, quick-turnaround, high quality and repeatable “ready for assembly” components, weldments, and assemblies for feeding your manufacturing and assembly processes in a timely manner.

Specifications

Features |

Bassett is a true turnkey supplier that can take your project from raw materials to finished assemblies that are plated and ready for assembly. |

Types of Fabricating |

Welding (MIG, TIG, Spot) Laser Cutting Roll Bending Saw Cutting Swaging Flaring |

Materials Used |

|

Production Runs |

From prototyping to high volume production |

Designing Assistance |

Bassett will help you design and tweak your component designs, material selections and assemblies to employ unique and precision Bassett processes such as laser tube cutting, roll bending, CNC machining, precision welding, end forming and sheet metal fabrication to optimize the fabrication and assembly process. The result is lower-cost, quick-turnaround, high quality and repeatable “ready for assembly” components, weldments, and assemblies for feeding your manufacturing and assembly processes in a timely manner. |

Quality Process and Certifications |

|

Preferred Drawing File Formats |

SolidWorks Files, Part, Assembly, Drawing, DXF, DWG, Adobe Photoshop Files, Adobe Illustrator Files, Template, Parasolid, IGES, STEP AP203/214, ACIS, VDAFS, VRML, STL, Catia Graphics, ProE Part, ProE Assembly, UGII, Inventor Part, Inventor Assembly, Solid Edge Part, Solid Edge Assembly, CADKEY, IDF, Rhino Files |

Secondary Services |

|

Industries Served |

At Bassett, we take on all jobs that fit our capabilities, for any industry. Below are examples of industries we have served in the past. We have created true turnkey components, weldments and assemblies for, but not limited to the following industries:

Agricultural, Alternative Energy, Appliance, Automotive, Computers, Construction, Defense, Distribution, Electronic, Fabrication, Furniture, Hardware, Health and Fitness, Heating and AC, Heavy Equipment, Lawn and Garden, Material Handling, Petroleum and Mining, Race Car & Stock Car, Refrigeration, Retail & Display, Solar Energy, Wind Energy |

Experience |

Bassett has over 75 years of experience in tube cutting, fabrication and assembly. |

Types of Service |

|