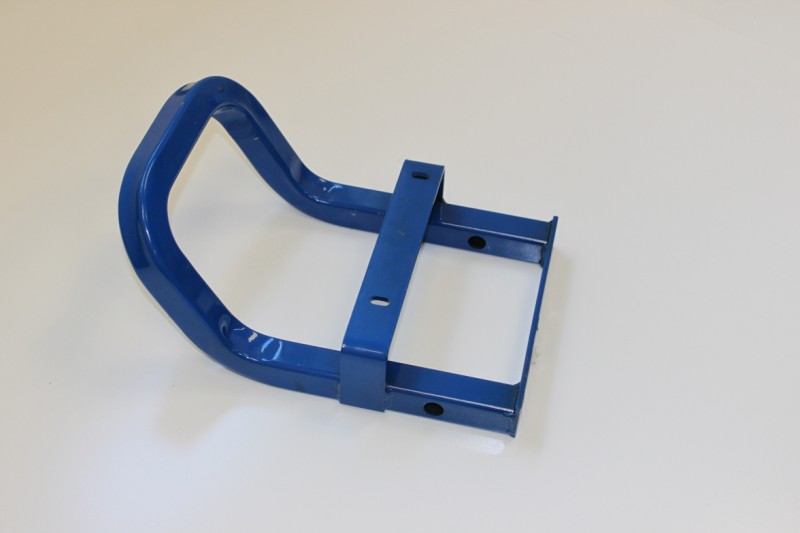

Tube Bending & Fabricating

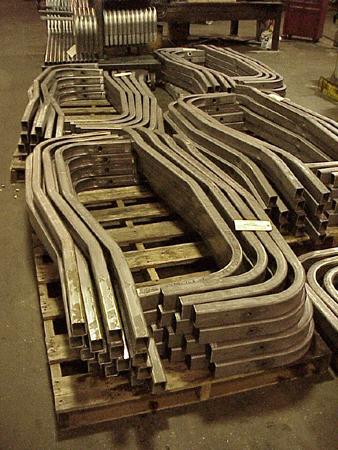

With over 75 years of experience in tube bending and fabrication, Bassett Industries, Inc. is a true vertically integrated turnkey tubular and sheet metal parts and assembly manufacturer. We take on a wide variety of precision tube fabrication processes from pre-cutting of raw materials to final production of finished, fabricated tubular components and assemblies.

Bassett Industries delivers quality ready-to-assemble tubular components, weldments and assemblies to industries including but certainly not limited to the Appliance, Automotive, Computer, Construction, Defense, Nuclear, Distribution, Electronic, Entertainment, Fabrication, Furniture, Hardware, Health and Fitness, Heating and AC, Heavy Equipment, Lawn and Garden, Material Handling, Petroleum and Mining, and Refrigeration industries.

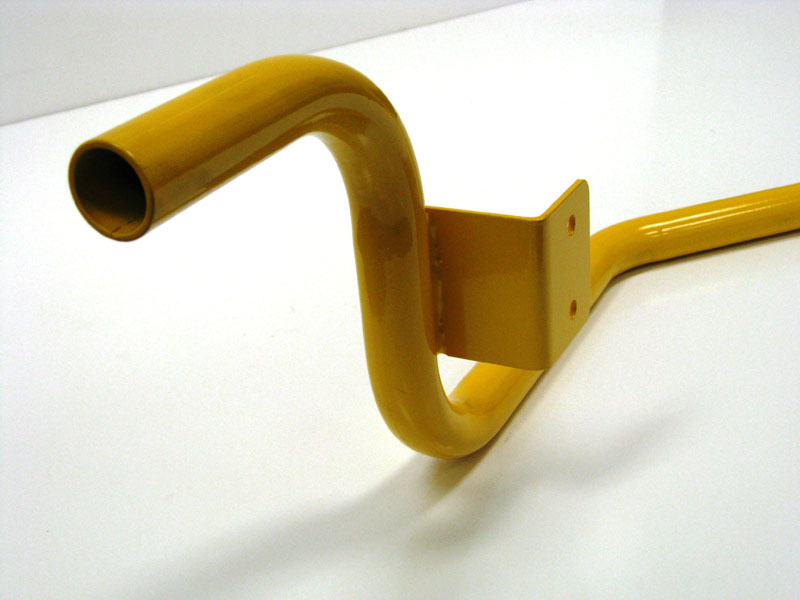

The Bassett tube bending process provides standard bend radii from tight 1D mandrel bends to large, sweeping roll bends and free form bending. We also offer bending of pre-coated and painted parts.

We fabricate metal tubes of length up to 27 feet and assemblies up to and over 80 feet. Mild steel, stainless steel, and aluminum are among the materials we use to produce these tubular components.

Bassett Industries, Inc. is equipped with state-of-the-art CNC tube benders with touch screen controls, which allows Bassett to produce complex bent parts. We use our existing tooling systems for bending and fabricating that not only facilitate faster part turnaround but also reduce tooling expenses. With 15 tube benders of various types and sizes, we fit the right machine to the product and well as provide redundancy to guarantee delivery in case one machine requires maintenance.

Moreover, we also have a dedicated customer support team to help you out with queries regarding in-house bend-die information.

Video Gallery |

|

Specifications

Materials Used |

|

Tube Size |

Bend

Fabrication

All bending and fabrication up to 27 feet length |

Tolerance |

+/- 0.005 inches Multi Axis CNC for close tolerances |

Tube Shapes |

Round Square Rectangular Oval |

Production Runs |

From prototyping to high volume production |

Designing Assistance |

Some basic ideas that can help in reducing the overall cost of a part by designing the part to be manufacturing friendly are provided below. For a more in depth analysis send us your drawings, or call one of our engineers.

Tube Bending Considerations:

Straight between bends: Allow 3x the OD of straight for clamping between bends and from the edge of the tube. This reduces the overall cost of part by reducing additional trim operations and increasing the bend rate. Bends closer than 3xD require compound tooling increasing tooling cost and reducing bend rates |

Quality Process and Certifications |

|

Preferred Drawing File Formats |

SolidWorks Files, Part, Assembly, Drawing, DXF, DWG, Adobe Photoshop Files, Adobe Illustrator Files, Template, Parasolid, IGES, STEP AP203/214, ACIS, VDAFS, VRML, STL, Catia Graphics, ProE Part, ProE Assembly, UGII, Inventor Part, Inventor Assembly, Solid Edge Part, Solid Edge Assembly, CADKEY, IDF, Rhino Files |

Secondary Services |

|

Industries Served |

At Bassett, we take on all jobs that fit our capabilities, for any industry. Below are examples of industries we have served in the past. We have created true turnkey components, weldments and assemblies for, but not limited to the following industries:

Agricultural, Alternative Energy, Appliance, Architectural, Automotive, Computers, Construction, Defense, Distribution, Electronic, Entertainment, Fabrication, Furniture, Hardware, Health and Fitness, Heating and AC, Heavy Equipment, Lawn and Garden, Material Handling, Nuclear, Petroleum and Mining, Race Car & Stock Car, Refrigeration, Retail & Display, Solar Energy, Wind Energy |