Category: Tube Fabricating

New State of the Art 5 Axis Laser Added to Bassett Industries’ Arsenal of Laser Cutting Equipment

Bassett increases its tube & formed sheet laser cutting capabilities with its acquisition of a new 4000 watt, 5 Axis laser for processing formed sheet metal parts, assemblies and large tube sections with a 33.4” Z stroke, 122” x axis and 86.6” y axis, and 4,400 lbs work piece capacity. Bassett’s purchase of the 5 Axis allows for flexibility and post form trimming and feature additions to parts that were previously impossible to cut. The new 5 Axis CO2 laser will allow Bassett engineers to work with our industry partners to quickly and cost effectively process large or small batch production without the need for dedicated and costly tooling.

Contact a Bassett rep today to learn more about our new and expanded capabilities of the 5 axis laser along with our other fabrication specialties. Contact us at 1-800-776-6440 or

Waterjet Cutting Services Now Available At Bassett Industries

Bassett Industries is pleased to announce the addition of waterjet cutting services to its already expansive list of manufacturing capabilities. The addition of waterjet cutting allows us to expand our engineering expertise to a wider variety of materials, increase production, and provide additional services to satisfy the demands of our clients.

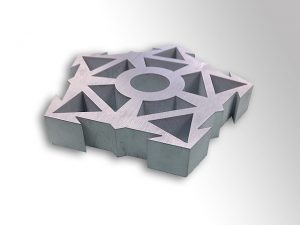

Waterjet capabilities include cutting sizes up to 275 in. long x 120 in. wide, with thickness up to12 in., pressure up to 90,000 psi and tolerances to +/-0.003 in. Dual dynamic head capabilities for lower costs, larger volumes and quicker turnaround. Parts in steel, aluminum, glass, stainless, copper, brass, marble, titanium, bronze, etc.

No heat affected zone, burr free cutting in an ISO9001 facility with additional services of sheet and tube laser cutting to 8.5″ dia, CNC tube bending and rolling to 8″ dia, MIG, TIG & robotic welding, press brakes to 350 ton x14 ft, CNC mills to 120″ travel and CNC lathes with multi heads and live tooling. Industries served include agriculture, health care, construction, job shops, laboratory equipment, marine, military, semiconductor and signage.

No heat affected zone, burr free cutting in an ISO9001 facility with additional services of sheet and tube laser cutting to 8.5″ dia, CNC tube bending and rolling to 8″ dia, MIG, TIG & robotic welding, press brakes to 350 ton x14 ft, CNC mills to 120″ travel and CNC lathes with multi heads and live tooling. Industries served include agriculture, health care, construction, job shops, laboratory equipment, marine, military, semiconductor and signage.

Reverse engineering, CAD services and 24 hr service available.

Bassett Industries Helps A Fabricator in Need After Hurricane Sandy

Bassett Industries has built a reputation as a quality fabricator of tubing for over 50 years, but we’re most proud of the quality people we have working for us. Bret Milks (Manufacturing Engineer at Bassett Industries) found out that the facility at Architectural Grille (a metal fabricator in Brooklyn, NY) was devastated by hurricane Sandy. Bret offered to help them to stay in business by running their jobs on the machinery at the Bassett facility.

Architectural Grille lost over $6 million in machinery, but losing customers by not delivering on their contracts would be the nail in the coffin. By taking on these jobs, Bassett Industries was able to help them stay in business while they put their shop back together again. “It’s definitely amazing the way he {Architectural Grille} has rebounded, and I’m glad things are working out for him,” Milks said of Giumenta and his company.

Continuous improvement of product through technology implementation

It is amazing to see the advancements in tube bending and cutting technologies in just ten or eleven years. The old process Bassett used on our U-Tubes in 1999 was to saw, cut, bend and drill in separate processes. We even had to outsource the drilling process to a local shop. This process alone had a one to two week turnaround.

Now Bassett has a state-of-the-art Tube Laser. Before we had 4 operations, this is now reduced to only two. Since we brought the tube laser online we have learned through various trials to get the highest efficiencies out of the production and minimize operations. We are now selling the U-Tube 10% cheaper than we were in 1999. This technology has completely changed the way we operate as an organization and streamlined our processes and efficiencies for many projects.

By leveraging new technologies which help eliminate outsourced operations, we have more control and know exactly where the parts are. This alone reduces lead times significantly. New technologies provide our customers with far more accuracy. This in turn, creates more flexibility. As an example, if there are small changes from the customer such as hole-size or location, we just reprogram that area and the revisions take very little time to implement. We can turnaround prototypes and projects in a very short amount of time. If tubular parts are eventually welded into an assembly, we can cut the parts so they have interlocking features which act as a self contained weld fixture, further eliminating additional tooling costs along with their associated lead-times.

We will work with the customer to optimize the part using the technology of the tube laser or any of our other state-of-the-art equipment. This typically leads to cost savings due to reduced production time, operations and material waste. We do this across the board in all our areas manufacturing areas, but the most dramatic cost savings continue to be with the tube laser.

The best advice is to let Bassett be involved in the design phase or show us parts you would like to reduce costs on. We may be able to offer a cost cutting option you might not have previously considered. In fact we have a medical parts customer who designs most of their parts solely around the capabilities of our tube laser.

Doug Fox

Bassett Industries Inc.